Products

- Plant component

- Equipment

- Project

- Service support

Products

CPM Constant-Pressure Modulating Valve

Concept

CPMI-2, CPMI-D60 and CPMO-2 are sanitary constant-pressure

valves. CPMI-2 and CPMI-D60 (Constant-Pressure Modulating Inlet)

maintain a constant pressure in the process line at the inlet side of

the valve. Typical applications are after separators, heat exchangers

or overflow valves. CPMO-2 (Constant-Pressure Modulating Outlet)

maintains a constant pressure in the process line at the outlet side of

the valve. Typical applications are before filling/bottling machines etc.

Working principle

The valves are remote-controlled by means of compressed air. A

diaphragm/valve plug system reacts immediately to any alteration of

the product pressure and changes position so that the preset pressure

is maintained.

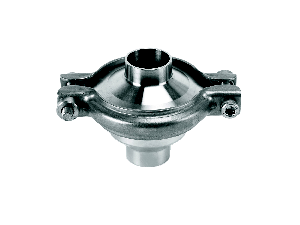

Standard design

The CPMI-2 and CPMO-2 consist of a valve body with valve seat,

cover, a valve plug with a diaphragm unit and a clamp. The cover and

the valve body are clamped together. The valve body and the seat are

welded together. The CPM-I-D60 consists of upper and lower valve

bodies, an inlet tube, a cover, a valve plug with diaphragm unit and

clamps. The cover and the valve bodies are clamped together.

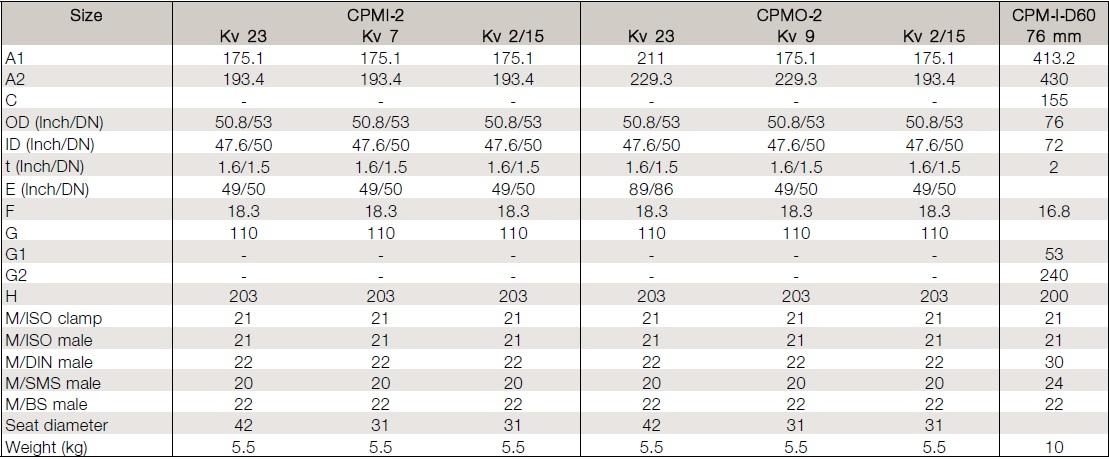

TECHNICAL DATA

Max. product pressure: . . . . . . . . . . 1000 kPa (10 bar).

Min. product pressure: . . . . . . . . . . 0 kPa (0 bar).

Temperature range: . . . . . . . . . . . . . -10°C to 95°C (EPDM).

Temperature range with upper diaphragm

in PTFE/EPDM: . . . . . . . . . . . . . . . -10°C to +140°C.

(Higher on request).

Air pressure (CPMI-2/CPMO-: . . . . . 0 to 800 kPa (0 to 8 bar).

Air pressure (CPM-I-D60): . . . . . . . . . 0 to 600 kPa (0 to 6 bar).

Flow Kv 23, fully open (Dp = 1 bar): . . Approx 23 m3/h.

Flow Kv 7 (Δp = 1 bar): . . . . . . . . . . Approx 7 m3/h.

Flow Kv 9 (Δp = 1 bar): . . . . . . . . . . Approx 9 m3/h.>

Flow Kv2/15, low capacity (Δp = 1 bar): Approx 2 m3/h.

(Alternative size) . . . . . . . . . . . . . . . (regulating area). Approx. 15

m3/h. (CIP area).

Flow range Kv60, fully open (Δp = 1 bar)

(CPM-I-D60) . . . . . . . . . . . . . . . . . Approx 60 m3/h.

PHYSICAL DATA

Materials

Product wetted steel parts: . . . . . . . . 1.4404 (316L).

Other steel parts: . . . . . . . . . . . . . . 1.4301(304).

Lower diaphragm: . . . . . . . . . . . . . . PTFE covered EPDMrubber

Upper diaphragm . . . . . . . . . . . . . . NBR

Air Connections

R 1/4" (BSP), internal thread.

Options

A. Male parts or clamp liners in accordance with required standard.

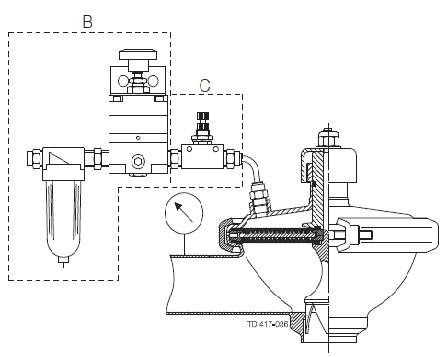

B. Air pressure regulating valve kit, 0-8 bar.

C. Air throttling valve for adjustment of regulating speed for the CPM-2 valve.

D. Booster for product pressure exceeding the available air pressure.

(Product pressure = 1.8 x air pressure).

E. US 3A version available on request for CPM-2 valves only

Material grades CPM-2

F. Upper diaphragm of PTFE covered EPDM and O-ring of FPM

covered EPDM, (for temperature 95-140°C).

G. Both diaphragms of solid PTFE and O-ring of FPM (for temperatures above 140°C).

Material grades CPM-I-D60

H. Upper diaphragm of PTFE covered EPDM.

I. Valve body seal rings of NBR or FPM.

J. Guide O-ring of FPM (for temperatures above 95°C).

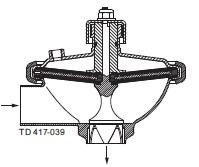

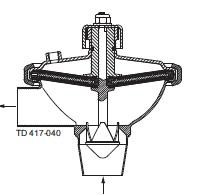

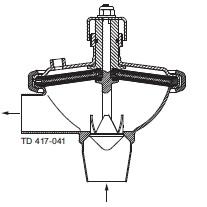

Fig. 1. Principle

CPMI-2 CPMO-2

a.Reduced product pressure.

CPMI-2 CPMO-2

b. Increased product pressure.

CPMI-2 and CPM-I-D60 opens at increasing product pressure and

vice versa.

CPMO-2 closes at increasing product pressure and vice versa.

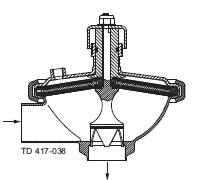

Diaphragm Unit

CPMI-2 and CPMO-2: The diaphragm unit consists of a stainless steel

disc which is divided into sectors and of flexible diaphragms which

are placed on each side of the sectors. CPM-I-D60: The diaphragm

unit consists of two flexible diaphragms supported by 12 stainless

steel sectors in between them.

Note!

For further details, see also instructions IM 70775 and IM70779

Fig. 2. CPMI-2 with pressure regulating valve and pressure gauge.

Next: LKC-2 Non-return Valve

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- Leave message