Products

- Plant component

- Equipment

- Project

- Service support

Products

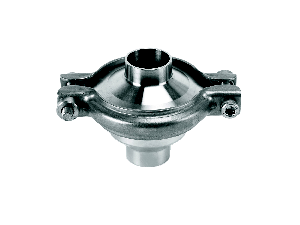

Unique Sampling Valve - Single Seat

Concept

The Unique Sampling Valve is a single seat valve designed for

sterilization before and after each sample. Valve body and connecting

pieces are made of one piece of material to avoid cracks and welding

pores.

Working principle

Sterilising: when the valve is closed, the channel between the valve

ports is open for sterilisation. If using steam, a small pressure relief

valve (optional) on the outlet is recommended. Sampling: when the

valve is opened, the stem and the membrane seal are retracted,

allowing liquid to pass.

Standard design

The valve consists of three parts, a valve body, an actuator and a

membrane seal. The rubber membrane seal is placed on the stem of

the actuator and works as a stretchable plug. The valve bodies and

actuators are interchangeable. The single seat valve can be upgraded

to a double seat valve by replacing the handle or actuator with an

upgrade kit - see ordering leaflet for accessories.

TECHNICAL DATA

Temperature

Temperature range: . . . . . . . . . . . . 1°C - 130°C

Max. sterilisation temperature,

dry steam (2 bar) . . . . . . . . . . . . . . 121°C

Steam must be dry, since condensate will damage the membrane

seal. It is recommended that the membrane seal be changed every

100 samples/sterilisations or in accordance with working conditions

or experience.

Pressure

Max. working pressure: . . . . . . . . . 600 kPa (6 bar)

Min. working pressure: . . . . . . . . . . 0 kPa (0 bar)

PHYSICAL DATA

Materials

Valve body: . . . . . . . . . . . . .1.4404 (316L)

Actuator: . . . . . . . . . . . . . . . 301, 303, 316L, PA 6.6/black, PTFE

Membrane seal: . . . . . . . . . .EPDM,

silicone

Options

A. Horizontal tube saddle valve body

B. Vertical tube saddle valve body

C. Varivent valve body

D. Weld, Tri-Clamp, Quick or thread connections

E. For accessories, please see ordering leaflet

Note!

For further information, see also instruction ESE01605.

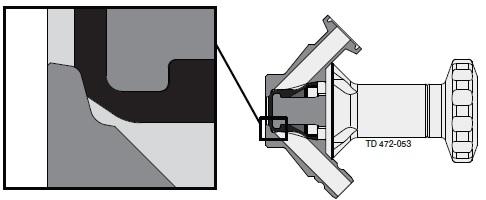

Closed valve

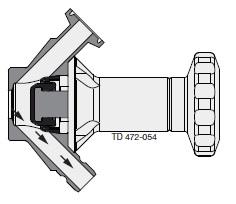

Open valve

By using the standard accessories, aseptic sampling is possible. The accessories are designed to ensure the right conditions when sterilising

(2 bar - 121°C). Heat insulating material is used to avoid burning.

Closed valve: Sterilising

When the valve is closed, the channel between the valve ports is open

for sterilisation. If using steam, a small pressure relief valve (optional)

on the outlet is recommended.

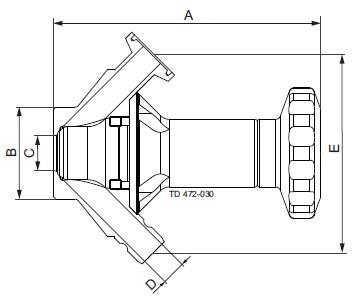

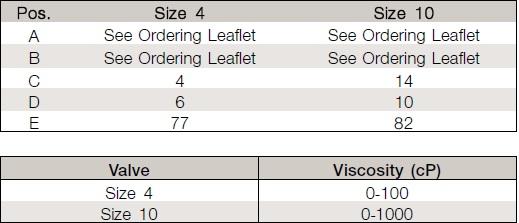

Fig. 1. Dimensions

Dimensions (mm)

Open valve: Sampling

When the valve is opened, the stem and the membrane seal are

retracted, allowing liquid to pass. By using the standard accessories,

aseptic sampling is possible. The accessories are designed to ensure

the right conditions when sterilising (2 bar - 121oC). Heat insulating

material is used to avoid burning.

The valve is available in two sizes:

- Size4forlow-viscosity products such as water, beer, wine and

liquid milk.

- Size 10 for high-viscosity products such as fruit yoghurt, syrup and

ice cream.

Valve bodies: Valve heads:

Tank (welding). Handle (0-6 bar)

Collared tube (welding). Handle, high pressure (6-10 bar)

Tri-Clamp Actuator (0-10 bar) air supply

max. 8 (bar)

Optional

Horizontal tube saddle (welding)

Vertical tube saddle (welding)

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- Leave message