Products

- Plant component

- Equipment

- Project

- Service support

Products

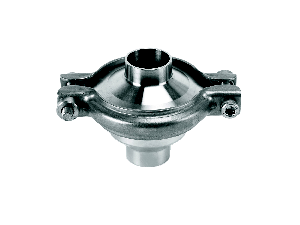

Unique mixproof vavle

Concept

The Unique Mixproof Valve is designed with user flexibility in mind.

The customer can choose additional options as required individually;

for example higher hygiene demands or higher resistance against

physically tough conditions. Please see next page for a graphic

overview of the modularity of the Unique Mixproof Valve.

Working Principle

Unique is remote-controlled by means of compressed air. The valve

is a normally closed (NC) valve.

The valve has two independent plug seals, forming a leakage chamber

between them under atmospheric pressure during every working

condition. In case of rare accidental leaking of product, this will flow

into the leakage chamber and be discharged through the leakage

outlet. When the valve is open, the leakage chamber is closed. The

product can then flow from one line to the other.

The valve can be cleaned and water hammer protected to any level

according to the needs in the specific process (see next page). There

is virtually no spillage of product when operating the valve.

TECHNICAL DATA

Max. product pressure: . . . . . 1000 kPa (10 bar)

Min. product pressure: . . . . . Full vacuum.

Temperature range: . . . . . . . . -5°C to +125°C (Depending on

rubber quality)

Air pressure: . . . . . . . . . . . .Max. 800 kPa (8 bar).

PHYSICAL DATA

Product wetted steel parts: . . . . . . . . . . . 1.4404 (316L).

Other steel parts: . . . . . . . . . . . . . . . . . 1.4301 (304).

Surface finish choose from the following:

Internal/external semi-bright . . . . . . . . . . Ra< 1.6

Internal Bright (polished) . . . . . . . . . . . . . Ra< 0.8

Internal/external Bright (internal polished) . . Ra< 0.8

Note! The Ra values are only for the internal surface.

Product wetted seals: . . . . . . . . . . . . . . EPDM.

Other seals:

CIP seals: . . . . . . . . . . . . . . . . . . . . . . EPDM.

Actuator seals: . . . . . . . . . . . . . . . . . . . NBR.

Guide strips: . . . . . . . . . . . . . . . . . . . . PTFE

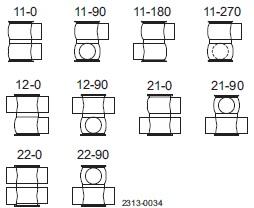

Valve body combination

Valve body combinations, example: type 11-00

1 Number of ports - lower valve body

1 Number of ports - upper valve body

00 Angle between ports

SpiralClean

The Alfa Laval SpiralClean system to clean the upper and lower

balanced plugs and leakage chamber. The system cleans more

efficiently, uses less cleaning fluid by ensuring that a directional flow

of CIP fluid reaches all the surfaces in much less time than with

conventional systems.

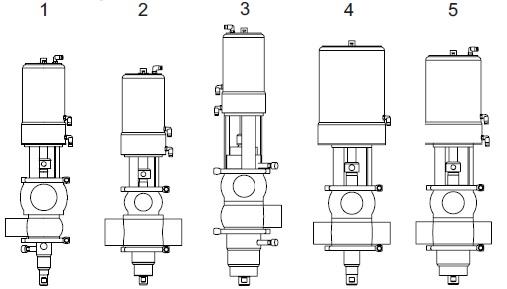

Selection guide

The drawings below give an overview of all options when choosing the

valve to fit your process, thus demonstrating the actual flexibility of

the Unique Mixproof Valve.

Size flexibility

The Unique Mixproof concept offers balanced and unbalanced

plugs, seat lift, CIP for the plugs and leakage chambers and any

combination in between.

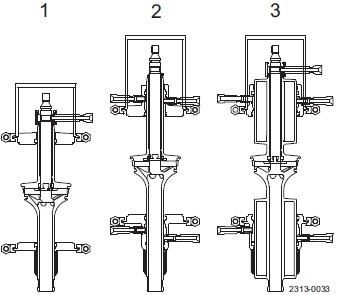

1. ISO 51 (2”)/ISO 76.1 (3”), 11-90, with spiral clean on lower

unbalanced plug, group 3 basic actuator incl. seat lift and seat

push

2. ISO 76.1(3”)/ISO 51 (2”), 22-90, with lower balanced plug, basic

actuator incl. seat lift and seat push

3. ISO 76.1(3”)/ISO 51 (2”), 22-90, with lower balanced plug, basic

actuator incl. seat lift and seat push

4. ISO 63.5 (2½”), 22-90, with spiral clean on leakage chamber,

unbalanced plugs, group 5 basic actuator

5. ISO 63.5 (2½”), 22-90, with lower balanced plug, group 4 basic

actuator incl. seat lift and seat push

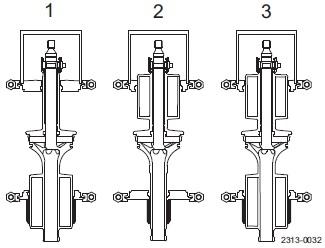

Balancing flexibility

1. Lower balanced plug

2. Upper balanced plug

3. Upper and lower balanced plugs

Hygienic flexibility (spiral clean options)

1. External CIP of leakage chamber

2. External CIP of leakage chamber, upper and lower unbalanced plug

3. External CIP of leakage chamber, upper and lower balanced plug Standard

OC Standard configurations

To assist you in the selection we have included some standard

configurations:

- UniqueBasic

- UniqueSeatClean

- Unique HighClean

- UniqueUltraClean

You can either choose these directly or add additional features

ensuring that the valve suits your specific needs.

Unique Basic has the basic components, providing significant safety

and leakage detection.

- Actuator without seatlift.

- Unbalanced plugs.

- No SpiralClean of leakage chamber or plugs.

Unique SeatClean meets the typical demands of a process valve in

the food and drink industry.

- Actuator with seat lift integrated.

- Balanced lower plug, Unbalanced upper plug.

- No SpiralClean of leakage chamber or plugs.

Unique HighClean is sure to meet your processing needs when

dealing with sticky products or if no recontamination can be accepted

at all.

- Actuator without seatlift integrated.

- Balanced lower and upper plug.

- SpiralClean of leakage chamber as well as of upper and lower plug.

Unique UltraClean meets the highest demands for hygienic

processing. It has:

- Actuator with seat lift integrated.

- Balanced lower and upper plug.

- SpiralClean of leakage chamber, upper and lower plug.

Options

- Male parts or clamp liners in accordance with required standard.

- Control and Indication: IndiTop, ThinkTop or ThinkTop Basic.

- Side indication for detection of upper seat lift

- Product wetted seals in HNBR, NBR or FPM

- Various internal/external surface finish

- 3A (sanitary standard) on request

- Mixed housing

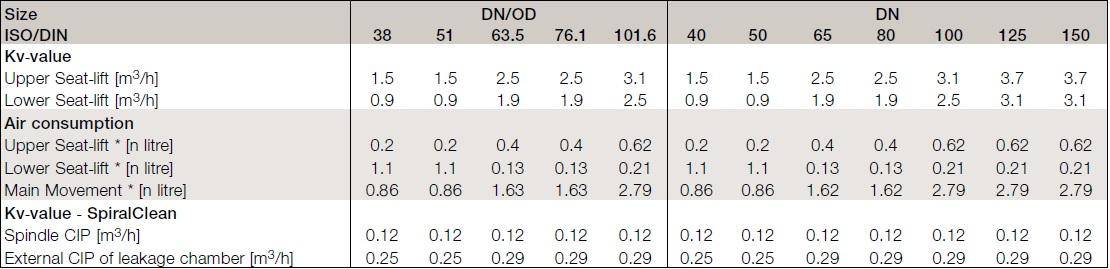

TD900-074-1

Note

* [n litre] = volume at atmospheric pressure

Recommended min. pressure for SpiralClean: 2 bar.

Formula to estimate CIP flow during seat lift:

(for liquids with comparable viscosity and density to water):

Q = Kv ·√Δ p

Q = CIP - flow (m3/h).

Kv = Kv value from the above table.

Δ p = CIP pressure (bar).

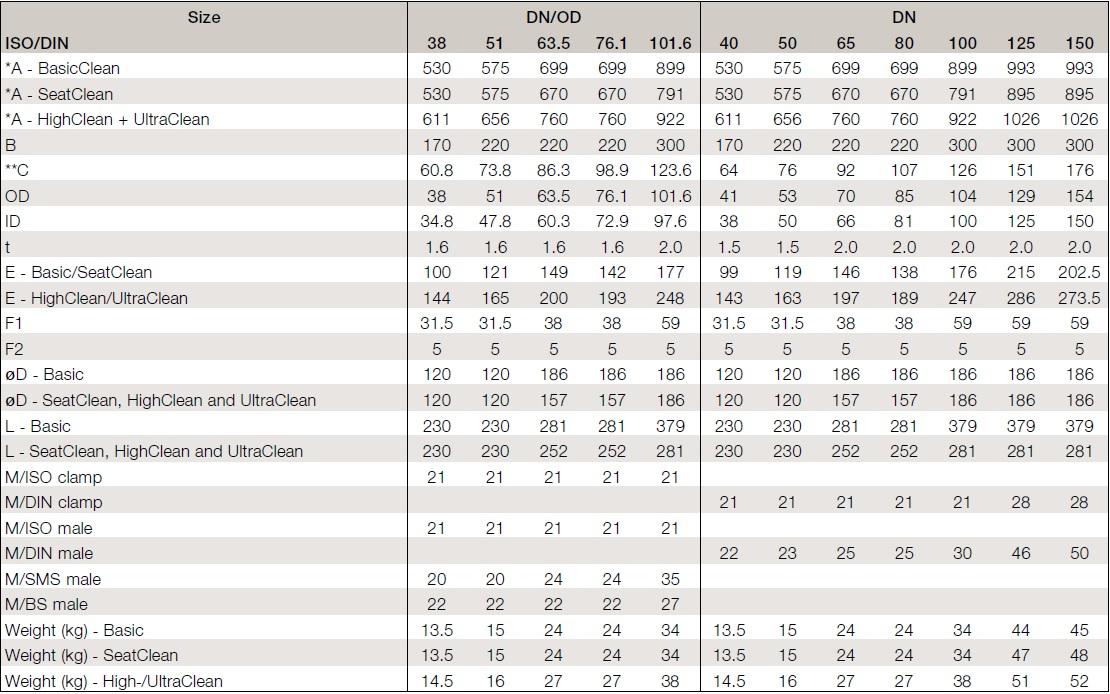

Actuator

Dimensions (mm)

Previous: Unique mixproof tank outlet vavle

Next: Unique SSV Aseptic

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- Leave message