Products

- Plant component

- Equipment

- Project

- Service support

Products

SRU Rotary Lobe Pump

Application

The SRU range of rotary lobe pumps has been designed for use

on wide ranging applications within the Brewing, Dairy, Food,

Pharmaceutical and Chemical industries. The SRU pump can handle

from low to high viscosity media with its characteristic smooth, low

shear pumping action being ideal for products such as creams, gels,

emulsions, aerated mixtures, and delicate cells and organic solids

in suspension.

The SRU range is suitable for CIP (Cleaning In Place) and conforms

to USA 3-A Sanitary Standard. In addition the SRU pump range is

certified by EHEDG (European Hygienic Equipment Design Group)

as fully CIP cleanable to their protocol. The SRU pump range is

also classified for use in potentially explosive atmospheres under the

ATEX Directive 94/9/EC Group II, Categories 2 & 3, with temperature

classification T1 to T4. The SRU range is compact in size and highly

efficient, capable of flow rates up to 106 m³/h and pressures up to

20 bar. The modular design provides for greater application flexibility

and cost effective maintenance.

The SRU range is compact in size and highly efficient, capable of flow

rates up to 106 m³/h and pressures up to 20 bar. The new improved

modular design provides for greater application flexibility and cost

effective easy maintenance.

Standard Design

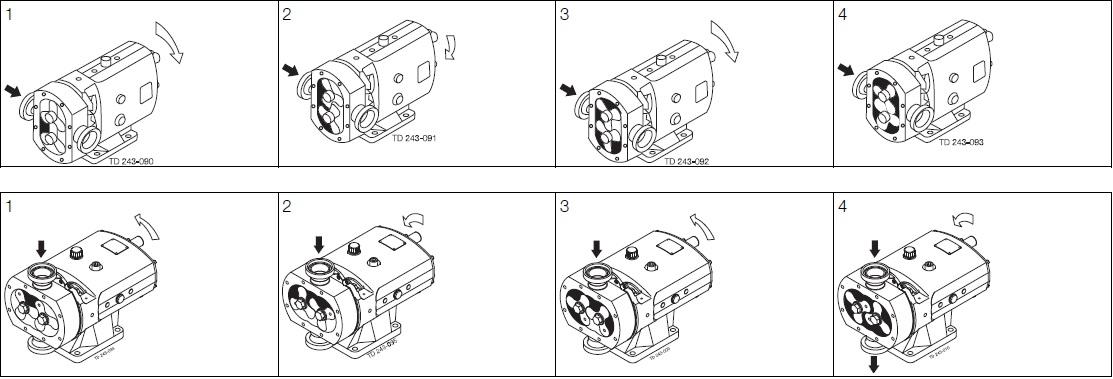

Pump Gearbox

The SRU pump with its conventional lobe pump design concept has a

robust cast iron gearbox, which provides maximum shaft rigidity and

easy oil seal replacement. The SRU range in series 1-4 has a universal

gearbox design. This gives the flexibility of mounting pumps with the

inlet and outlet ports in either a vertical or horizontal plane by changing

the foot and its position. The SRU range in series 5 & 6 has dedicated

gearbox castings, which also allows the inlet and outlet ports to be in

either the vertical or horizontal plane.

Pump head Construction

The SRU in standard specification has sanitary design full bore inlet

and outlet ports to International Standards, maximising inlet and

outlet port efficiency and NPSH characteristics. Enlarged diameter

and rectangular ports are also available to handle very high viscosity products.

The SRU in standard specification has tri-lobe rotors with the option

of bi-lobe rotors for handling fluids containing large delicate solids. All

rotors are available in three temperature ratings allowing the pump to

be operated at maximum process temperatures of 70°C, 130°C and

200°C for both fluid pumped and CIP.

Materials of Construction

Pump gearbox - high quality grey cast iron.

Pumphead - product wetted components in 316L .

Product wetted elastomers of EPDM, NBR, FPM all FDA conforming.

Also PTFE for chemical applications.

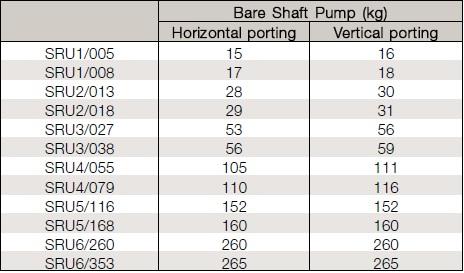

Weight

Shaft Seal Options

- Single or single flush/quench (steam barrier for aseptic

application) R90 or Hyclean type mechanical seals.

- Double R90 type mechanical seal for flush.

- Packed gland (unflushed or flushed versions).

Note: EHEDG compliance only for Hyclean type mechanical seals.

Materials for Mechanical Seals

Carbon/Stainless steel, Tungsten Carbide/Tungsten Carbide, Silicon

Carbide/Silicon Carbide or variations of these materials to suit fluid

being pumped and/or application requirements. (N.B. Material variants

are not available on all R90/Hyclean seal types)

Pump Sizing

In order to correctly size a rotary lobe pump some essential information

is required. Provision of this information listed below enables our

Technical Support personnel to obtain the optimum pump selection.

Product/Fluid Data

- Fluid to be pumped

- Viscosity

- SG/Density

- Pumping temperature, minimum, normal and maximum

- Cleaning in Place temperature(s), minimum, normal and maximum

Performance Data

- Flow rate, minimum, normal and maximum

- Discharge head/pressure (closest to pump outlet)

- Suction condition

Standard Specification Options

- Specification of inlet and outlet ports (Screwed male to BSP,

DIN11851, Rdg, SMS, ISS/IDF, RJT, IAMD/3A, Tri-clamp and other

standards, or Flanged to BS4504/DIN2533, ASA/ANSI 150, BS10E

and other standards).

- Rotorcase Cover with integral Pressure Relief Valve.

- Heating/Cooling Saddle Jackets for Rotorcase and Jacket for

Rotorcase Cover (not available when relief valve fitted).

- Bi-lobe Rotors in stainless steel and non-galling alloy.

- Electropolished product wetted components.

- Full material traceability on request to BS EN10204 3.1

- Electroless nickel plated gearbox.

- ATEX compliance.

- Complete pump unit comprising: Pump + Baseplate (mild or

stainless steel) + coupling with guard + Geared electric motor

suitable for (or supplied with) frequency speed control or manual

variable speed drive (advise motor enclosure and electrical supply)

Working Principle

The positive displacement of the SRU pump is provided by non-contacting, contra rotating tri-lobe or bi-lobe rotors within a fully swept pump chamber.

All SRU pumps are capable of bi-rotational flow without modification.

Fig. 1

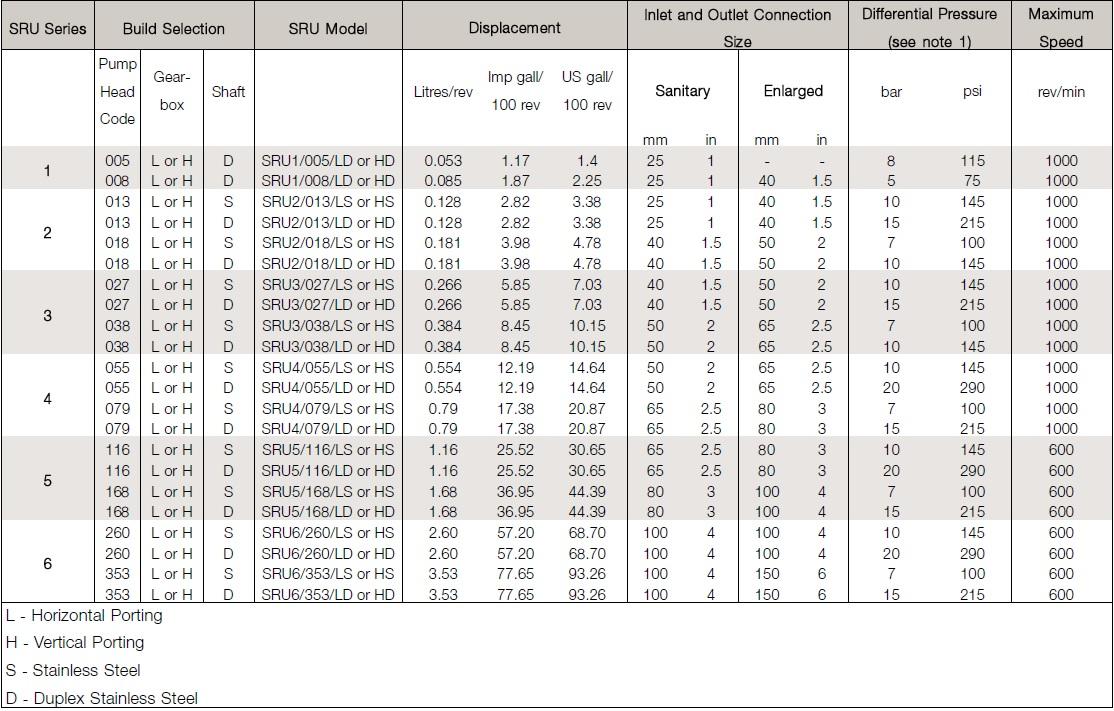

Flows/Pressures/Connections

>

Note 1. These pressure ratings may vary for pumps with certain threaded connections.

Previous: SX Rotary Lobe Pump

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- Leave message