Products

- Plant component

- Equipment

- Project

- Service support

Products

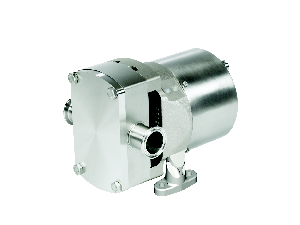

OptiLobe Rotary Lobe Pump

Application

The OptiLobe range of rotary lobe pumps combines cost-effective

simplicity with Alfa Laval quality and reliability. The OptiLobe range has

been developed for general applications within the Dairy, Beverage

and Food Industries.

The ’OptiLobe’ pump range has been certified by EHEDG (European

Hygienic Equipment Design Group) as fully CIP cleanable to their

protocol, and therefore is ideally suited for applications where

cleanability is paramount.

Also the OptiLobe pump range conforms to USA 3-A Sanitary

Standard and all media contacting components are FDA compliant.

The pump features the "EasyFit" front loading seal which allows quick

and easy inspection or replacement without the need for pipework

disassembly.

The ’OptiLobe’ pump range is compact, efficient and capable of flow

rates up to 48 m³/h and pressures up to 8 bar.

TECHNICAL DATA

Pump Sizing

In order to correctly size a rotary lobe pump some essential information

is required. Provision of this information listed below enables our

Customer Support personnel to obtain the optimum pump selection.

Materials

Gear canister . . . . . . . . . . . . 304 stainless steel.

Bearing housing . . . . . . . . . . electroless nickel plated cast iron.

Shafts . . . . . . . . . . . . . . . . duplex stainless steel.

Pumphead . . . . . . . . . . . . . product wetted components in 316L.

Product wetted elastomers . . . EPDM, FPM all FDA conforming.

Mechanical Seals . . . . . . . . . Carbon/Stainless Steel, Carbon/Silicon

Carbide or Silicon Carbide/Silicon Carbide.

OPERATING DATA

Product/Fluid Data

- Fluid to be pumped

- Viscosity

- SG/Density

- Pumping temperature, minimum, normal and maximum

- Cleaning in Place temperature(s), minimum, normal and maximum

Performance Data

- Flow rate, minimum, normal and maximum

- Discharge head/pressure (closest to pump outlet)

- Suction condition

Weight

Shaft Seal Options

- EasyFit type single or single flush/quench mechanical seals.

All sealing options are fully front loading and fully interchangeable.

Specialised seal setting of the mechanical seal is not required as the

seal is dimensionally set on assembly. This feature further enhances

fast and efficient on-site seal interchangeability.

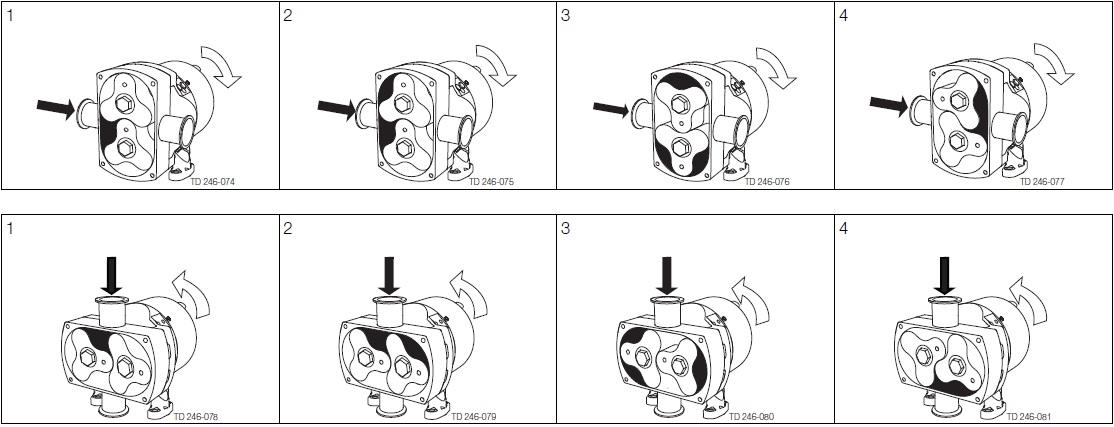

Standard Design

Pump Gearbox

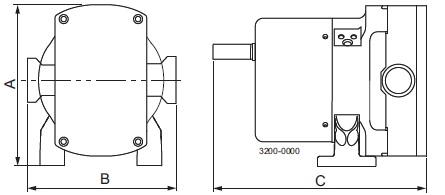

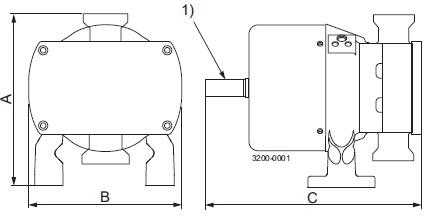

The OptiLobe pump range has a universal gearbox design with the flexibility of mounting inlet and outlet ports in either a vertical or horizontal plane

by simply changing the foot position. A stainless steel gear canister and electro-less nickel plated bearing housing provides a clean, paint free

corrosion resistant external finish.

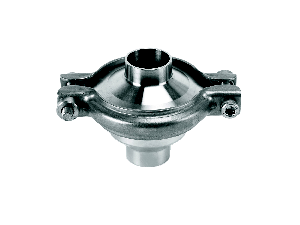

Pump head Construction

The OptiLobe pump range has sanitary design full bore inlet and outlet ports to International Standards, maximising inlet and outlet port efficiency and

NPSH characteristics. Pumps are fitted with tri-lobe rotors rated to 130°C facilitating use with CIP processes.

Standard Specification Options

- Specification of inlet and outlet ports (Screwed male to DIN11851 to BS 4825, SMS, ISS/IDF, RJT and Tri-clamp).

- Complete pump unit comprising: Pump + Baseplate (mild or stainless steel) + coupling with guard + Geared electric motor suitable for (or supplied

with) frequency speed control or manual variable speed drive (advise motor enclosure and electrical supply)

Working Principle

The positive displacement of the OptiLobe pump is provided by non-contacting, contra rotating tri-lobe rotors within a fully swept pump chamber. All

OptiLobe pumps are capable of bi-rotational flow without modification.

Fig. 1

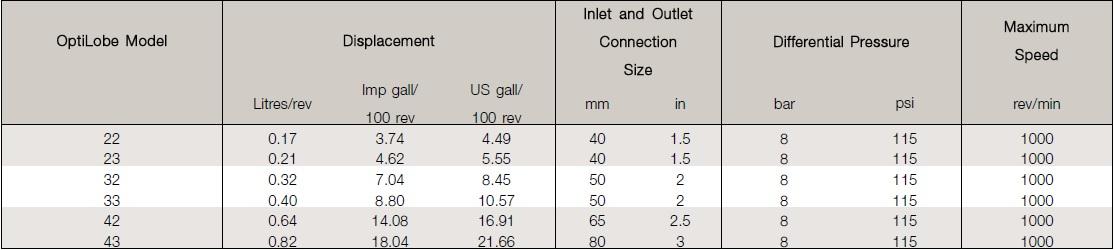

Flows/Pressures/Connections

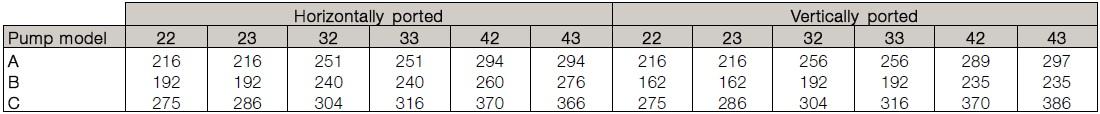

Dimensions (mm)

Horizontally ported

Vertically ported

Previous: SRU Rotary Lobe Pump

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- Leave message