Products

- Plant component

- Equipment

- Project

- Service support

Products

MR-166S, -185S, -200S, -300 Liquid-Ring Pump

Application

MR is a liquid-ring pump specially designed for pumping liquids

containing air or gas.

The pump is for use in food, chemical, pharmaceutical and similar

industries.

The pump is mainly used for CIP-return application.

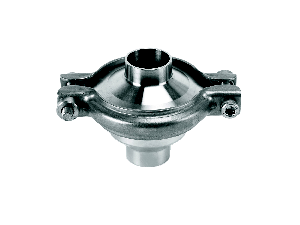

Standard design

All product wetted parts, i.e. pump casing, casing cover and impeller

are made of acid-resistant steel AISI 316L. Seals are made of EPDM

rubber.

Cap nuts, legs, leg brackets and shroud are made of stainless steel

AISI 304. The shroud has noise absorbing lining inside.

MR-166S, 185S and 200S: Adaptor is in cast iron which is zinc coated

and laquered making it highly corrosion resistant.

Shaft seal

On MR-166S, -185S and 200S, the mechanical single seals have

stationary seal rings of acid-resistant steel AISI 329 and rotating seal

rings of carbon.

The MR-300 has mechanical single seal with stationary seal rings of

carbon and rotating seal rings of acid-resistant steel AISI 329.

TECHNICAL DATA

Motor

Standard foot-flanged motor acc. to IEC metric standard 4 pol =

1500/1800 rpm. at 50/60 Hz.

IP55 (with drain holes with labyrinth plug), insulation class F.

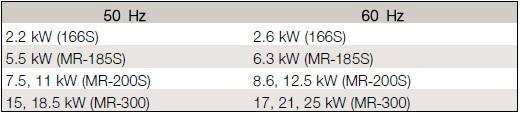

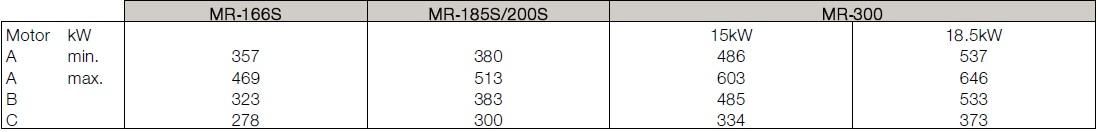

Motor sizes

OPERATING DATA

Pressure

Max. inlet pressure: . . . . . . . . . . . . . 400 kPa (4 bar).

Temperature

Temperature range: . . . . . . . . . . . . . -10°C to +140°C (EPDM).

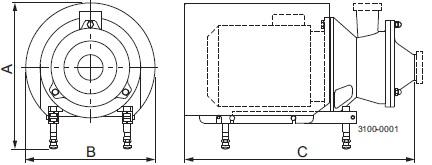

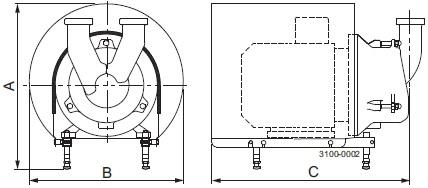

Dimensions (mm)

MR-166S/-185S/-200S MR-300

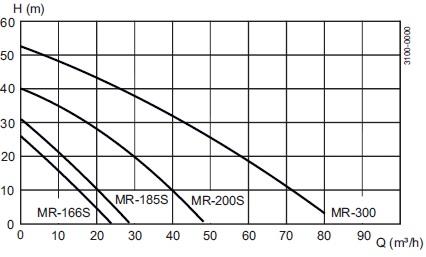

Volumetric flow MR-166S, -185S, -200S and -300

Options

A. Other voltage and frequency.

B. Flameproof motors (EEXE and EEXD).

C. Pump without shroud and legs.

D. Pump without shroud.

E. Adaptor in stainless steel AISI 304 (MR-185S and MR-200S only).

F. Noise reduction valve.

G. Product wetted seals of Nitrile (NBR) or Fluorinated rubber (FPM).

H. Stationary seal ring with sealing surface of Silicon Carbide

(MR-185S and MR-200S only).

I. Rotating seal ring of Silicon Carbide (MR-185S and MR-200S only).

Ordering

Please state the following when ordering:

- Pumptype.

- Voltage and frequency.

- Connections.

- Flow rate, pressure and temperature.

- Density and viscosity of product.

- Options.

Note!

For further information, see also instruction IM70719 and M70733.

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- ·Welcome toSuntyech Process Engineering (Shang Hai) Co.,Ltd.!!!

- Leave message